Plywood

What is Plywood?

Plywood is a versatile type of engineered wood panel used in construction projects. The face veneers in a standard plywood panel are of greater quality than the core veneers. The purpose of the core layers is to improve resistance to bending forces by increasing the spacing between the outer layers where the bending stresses are greatest.

Although plywood production dates back to the era of the pharaohs, the first industrial production took place in America in 1896. After this date, its usage areas have expanded. In our country, the first production coincides with 1932 and continues to develop.

There is a representation of an example application of plywood as a cladding material. As you can see plywood can be apply in a mechanical was because the connection type of the material is mechanical connection. You can use horizontal battens in order to place plywood.How is plywood made?

First, the tree trunks are collected (there are lots of tree types to use) and the outer bark is peeled off. Then, the peeled tree trunks are put into the machine to be cut as thin as paper. Afterwards, the thin pieces are inserted into the squeezing machine to be dried. The parts that have been squeezed out are covered with glue and sent to the pressure machine. There are two types of pressure machines. First of them is cold pressure machine and the second one is hot pressure machine. The glued pieces are sent to cold one.After that, the pressured pieces are sent to the hot pressure machine. 800 tons of weight is applied in themachine. Finally, plywood is taken to the cutting area in order to get ready for the distribution.

Generally, three types of glue are used, these are urea formaldehyde, melamine formaldehyde, and phenol formaldehyde glues. Plywoods using urea formaldehyde glue are general purpose plywoods and are suitable for indoor use. When phenol formaldehyde glue WBP is used, water plywood suitable for outdoor weather conditions is obtained. By adding a certain amount of melamine formaldehyde glue to the urea formaldehyde glue, plywood resistant to humid environment is obtained indoors.There should be at least 5 or 7 layers. The higher the number of layers, the stronger the strength. The hardness and density of the inner material used in the plywood layers should be of the same wood type, if different types of wood products are used, warping and rotation problems in the plywood may occur, reducing the material quality and strength. There is a small representation sheme that shows the journey of plywood. Plywood typesBeech Marine PlywoodBeech plywood, made of WBP water-resistant marine glue produced from domestic and imported beech wood, can be easily used outdoors, on billboards, furniture, automotive, construction, boat, roofing, packaging, machine model mold, caravan and container floors. Marine plywood is resistant to moisture and being kept in water.

Poplar PlywoodPoplar plywood obtained from domestic and imported high quality poplar trees can also be produced from WBP glue upon request. Poplar plywood can be used in the construction industry, auto interior design, packaging industry, hobby, roofing, machine model mold, caravan and door manufacturing.Exotic Marine PlywoodExotic plywoods are made by ozigo,okume, tetra, eyong, onzabili, naga etc. trees. They are imported from African region countries. Exotic marine plywood obtained from trees is resistant to standing in boiling water for 72 hours. It is produced from WBP glue. These plywoods are certified by Rina and Türk Loydu, if requested. The usage areas are; yacht, boat, maritime, construction, exterior design, decoration furniture, automotive, exterior advertising and packaging industry. Pine Marine Plywood

Manufactured from pine trees imported from Brazil and South America, it is imported in thicknesses of 8 mm and above, and is resistant to water and moisture. Pine plywood can be easily used in the construction industry, roofing, decoration, and environmental closure. Pine Plywood is divided into 2 classes as B/C and C/C quality.

Birch Marine PlywoodIt is produced from birch trees imported from Russia, Ukraine and northern countries. It is water and moisture resistant. You can easily use birch plywood in decoration, open space, packaging industry and automotive industry.Flexible Plywood

It can be used in places such as curved columns, arches, yachts, boats. It has streching and bending properties. Flexible Plywood has a vast place in current projects. Because it can be used in lots of areas, designers mostly prefer this plywood in new projects.

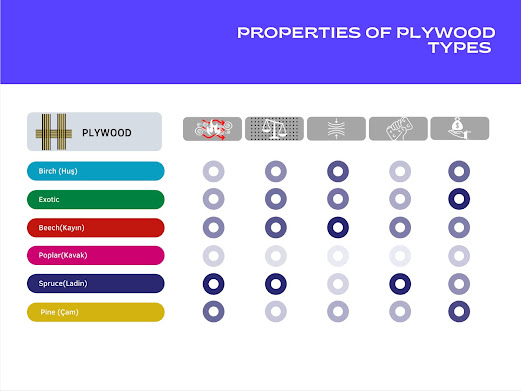

There is a sheme that shows the usage areas of plywood depends on the type of the wood.

tree types | density (kg/m3) | Bending strength (N/mm2) | Margin of exposure Bending strength (N/mm2) | Shear strength (N/mm2) | compression (N/mm2) |

Birch | 610 - 660 | 120 - 144 | 13300 - 16200 | 11.8 - 14.2 | 49 - 60 |

Spruce | 400 - 430 | 65 - 77 | 10000 - 12000 | 5 - 5.7 | 40 - 50 |

Beech | 640 - 720 | 90 - 125 | 12300 - 16400 | 7.7 - 10 | 52 - 64 |

Douglas pine | 550 | 72 | 12700 | 7.3 | 47 |

Buildings and designs designed using Plywood

Plywood Office- RAW Architecture

https://www.archdaily.com/804020/parabolic-plywood-office-raw-architecture

Winnipeg Skating Shelters- Patkau Architects

Acoustic Environments- AREA and Electrotexture

https://www.archdaily.com/770555/the-porthole-toma

Resources

https://www.matweb.com/search/datasheet_print.aspx?matguid=bd6620450973496ea2578c283e9fb807

https://www.ozturkkontrplak.com/4-mm-egzotik-marin-kontrplak-fiyati-kontraplak-fiyatlari-detay_6

https://www.yapikatalogu.com/arama?q=KONTRPLAK

https://www.centuryply.com/blog/can-plywood-be-waterproof-here-are-the-facts

https://huskontrplak.com/plywood-nedir-nerelerde-kullanilir/

https://huskontrplak.com/plywood-nedir-nerelerde-kullanilir/

https://www.centuryply.com/blog/can-plywood-be-waterproof-here-are-the-facts

Yorumlar

Yorum Gönder